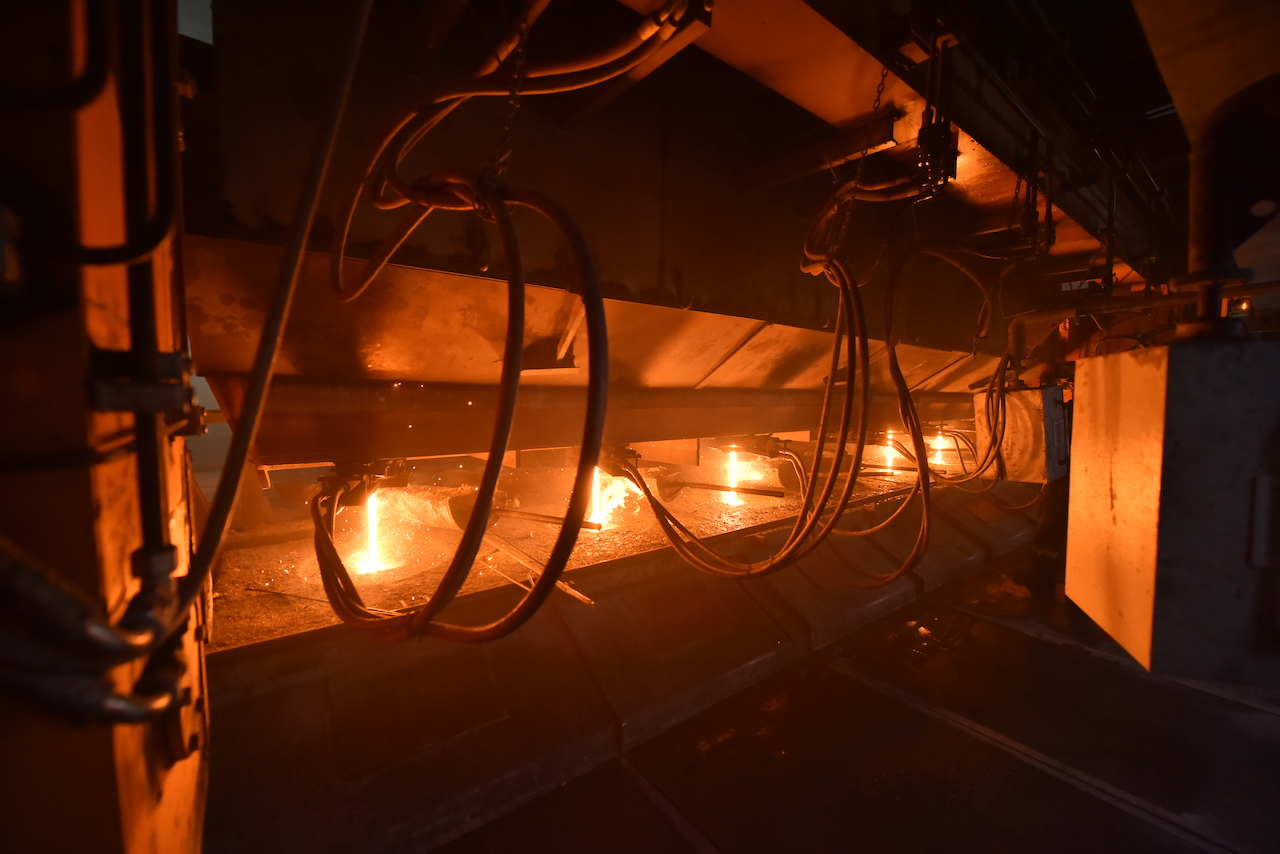

Submerged Arc Furnace

A submerged electric arc furnace (SEAF) is a variation of the Electric Arc Furnace. The defining characteristic of a SEAF is that the electrodes and charge materials are fully submerged in the molten metal, which results in a number of benefits. This design allows for greater energy efficiency and precise temperature control, making it an ideal choice for the production of ferroalloys. The intense heat generated by the electric arc in the SEAF enables fast melting and refining times, which is crucial for producing high-quality ferroalloys. Additionally, the precise temperature control that is inherent in the submerged design guarantees the desired chemical composition of the final product, making it a consistent and reliable choice for manufacturers.

Contact us today and to get more information about SEAFs!