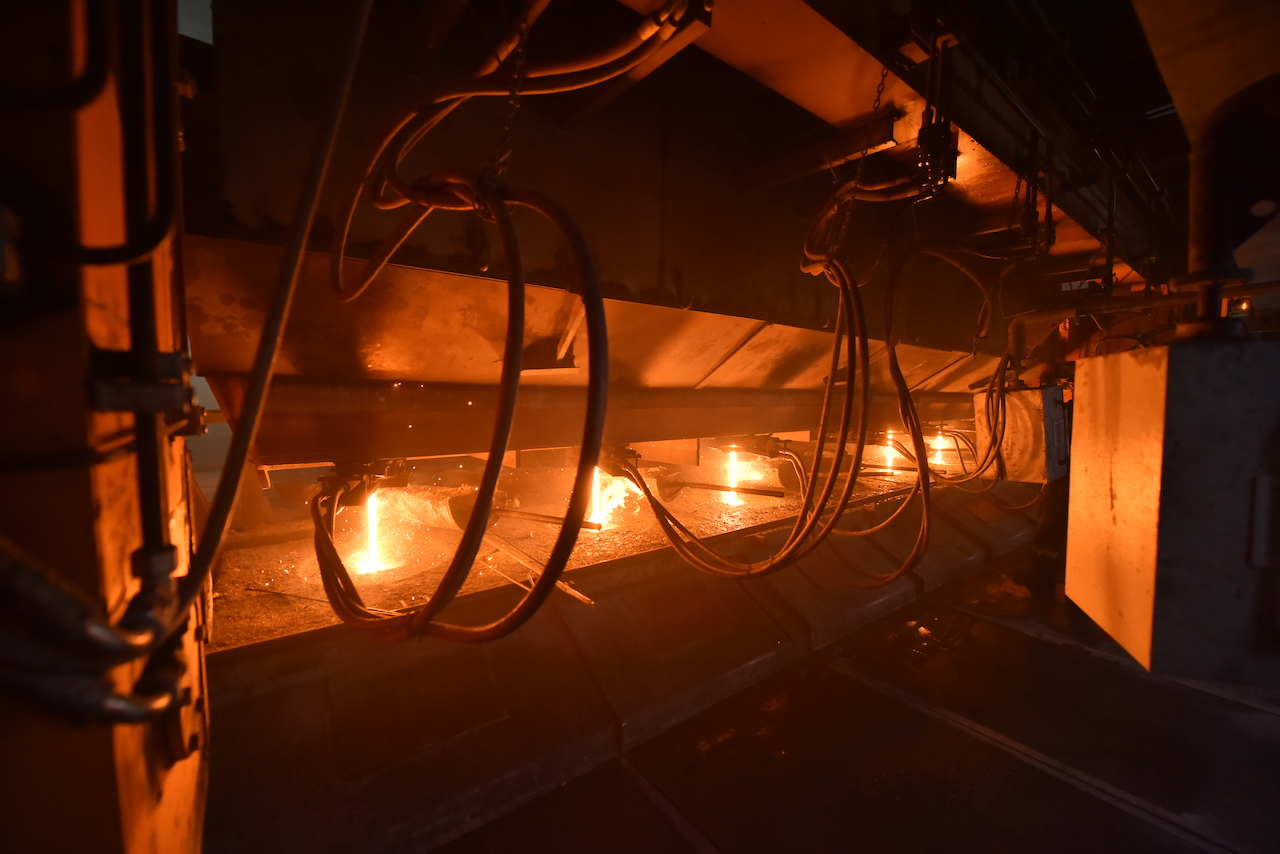

Casting Conveyor System

The Casting Conveyor Machine is an essential tool in the production of ferroalloys. It is used to transfer molten metal from a ladle to the mold, ensuring a smooth and efficient casting process. The machine consists of a conveyor belt that is driven by a gear motor and can be adjusted to a speed of 0-12 meters per minute, depending on the volume of molten metal being poured. The conveyor is equipped with a feeding platform that is actuated hydraulically, allowing the ladle to be rotated and tilted to discharge the molten metal onto the fixed mold. The conveyor also features a pressurized water spray that is applied to cool the molten steel faster in the last 15 meters. The metal is transferred along the conveyor for a distance of approximately 42 meters before falling onto impact plates at the end of the conveyor. The metal is then collected in a hopper of various sizes.

Contact us today to get more information!